OPTIMA EDGE RAINSCREEN

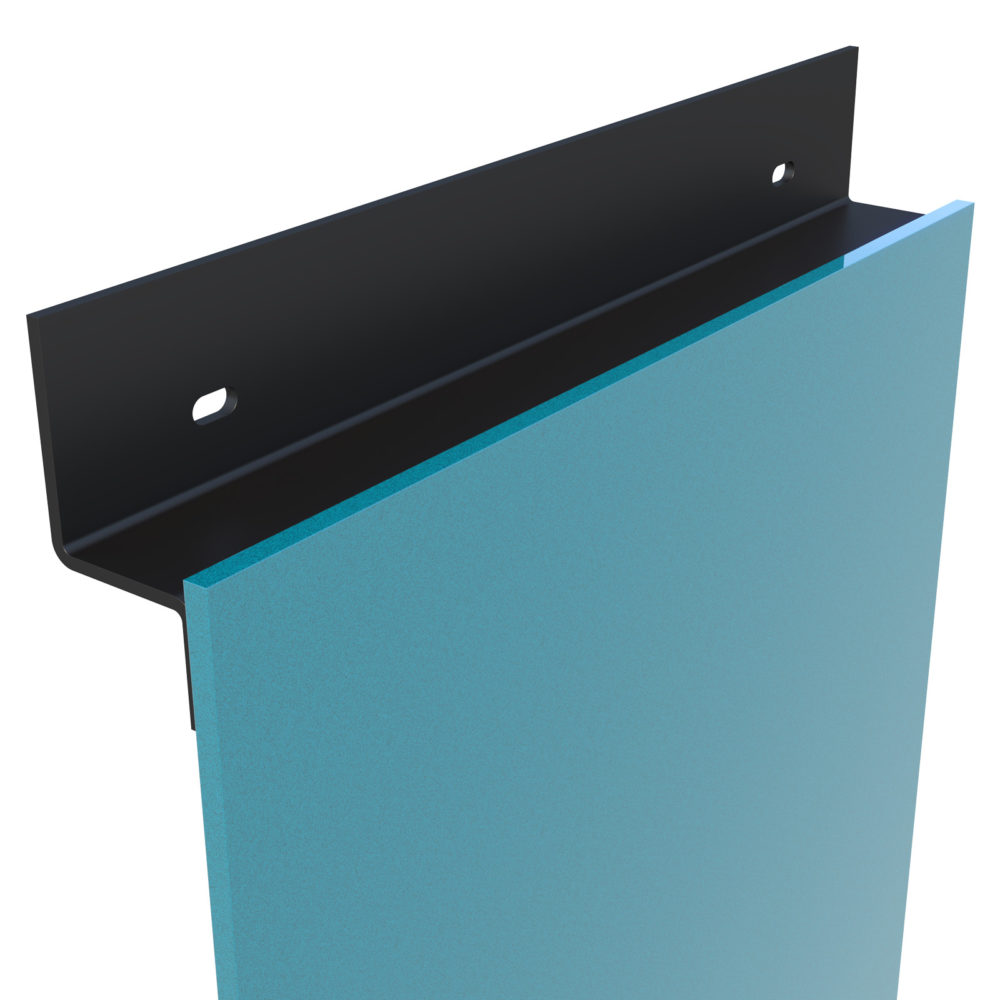

INTRODUCING A SECRET FIX RAINSCREEN WITH A FLAT PANEL APPEARANCE AND A CLEAN CRISP EDGE.

Optima Edge; a desirable variation on the innovative FC+ secret fix hook on rainscreen model. Taking the very best of the FC+ system , the team made significant modifications to give the new system a floating panel appearance with a clean, crisp edge.

BENEFITS OF THE OPTIMA EDGE SYSTEM

The Optima EDGE Rainscreen system offers a superior approach to traditional cladding with a range of benefits that enhance the functionality and aesthetic of your building. Designed for both aesthetic appeal and performance longevity, it's the ideal solution for modern architectural needs.

- Independently Tested: Certified to meet cwct's rigorous specifications for rainscreen cladding.

- Drained & Ventilated: Features a labyrinth-jointed series of panels creating an effective weather shield.

- Non-Adhesive fixing methods: For true A1 and A2 cladding, mechanical fixing methods are solely used to avoid the use of adhesives.

- Discreet Fixings: Employs discreet fixings in vertical panel recess, maintaining the benefits of a drained and ventilated façade.

- Precision Engineering: Superior design and manufacturing techniques prevent metal thickness build-up at joints.

- Seamless Integration: Engineered to integrate with all other building façade elements.

- Fire Safety: Fire tested to BS8414-2:2015 and classified to br135 for high rise buildings.

- Comprehensive Range: Offers a full range of Euroclass A1 and A2 – s1,d0 panel materials from 2mm – 4mm here.

- Bespoke details: Can also be incorporated click here

- System guarantees: Available upon request

- NBS specifications: Available and can be tailored to your project needs

- Technical arrangement details: Available here

- CAD details: Are available, please contact our technical team 0191 5879213

- Experience TFC+: In our interactive VR here

GET IN TOUCH TO ARRANGE A CPD

OPTIMA EDGE PANEL VARIETIES AND SIZES

Versatile Sizes and Materials for Every Architectural Need

Optima EDGE Panels offer a versatile and high-quality solution for modern architectural needs, available in various sizes and finishes to accommodate different design aesthetics and performance requirements. With materials ranging from 1.5mm to 4mm and available in Anodised Aluminum, PPC Aluminum, Pre-Paint, A1 & A2 ACM, Copper and Zinc, these panels are designed to meet a variety of architectural demands. Sotech’s state of the art machinery allows flexibility in precision manufacturing of panels upto 3800mm x 1300mm, providing ample coverage for large areas. The option for bespoke sizes ensures that even the most unique design visions can be brought to life. The different material options offer a balance between durability, aesthetic, and fire safety, making them a suitable choice for a wide array of construction needs.

Contact us for maximum and typical panels sizes available

DURABLE AND ADAPTIVE SUBSTRUCTURE

Building a Reliable Foundation with Quality Materials

The Optima EDGE system isn’t just about the panels; the substructure is equally important in ensuring longevity and performance. Built using materials from quality brands, the system guarantees reliability and durability. The system’s adaptability is evident in its suitability for all types of wall constructions, whether for new builds or refurbishments. The fully adjustable system allows for precise alignment and levelling of the cladding zones, accommodating variations in insulation thickness and wall irregularities. This precision ensures a flawless finish and long-lasting performance, keeping the project’s aesthetic and structural integrity intact over time.

INSTALLATION AND VENTILATION SOLUTIONS

Ease and Versatility in Application

Finally, the Optima EDGE’s system’s installation and backing walls are designed with ease and versatility in mind. Compatible with various types of external insulation and wall constructions, it offers solutions for easy installation. The system’s adjustability, along with the use of wafer head, self-tapping stainless-steel screws, ensures a secure and precise installation. Ventilation zones behind the panels are often designed to exceed CWCT minimum requirements, considering structural rails and other constraints. With such detailed attention to functionality, adaptability, and aesthetic, the Optima EDGE system provides a comprehensive solution for modern cladding needs.

ANODISED ALUMINIUM

Anodising is an A1 non-combustible finish. It is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts.

Due to the nature of the anodising process and the tight quality controls on both the aluminium and the surface treatment, anodising has a homogeneous (matching & consistent) appearance.

Colours, textures and patterns can be incorporated in the anodic film, enhancing the natural metallic appearance without affecting the total UV resistance of the rainscreen cladding.

Anodising enhances the natural qualities of aluminium further; it permits a strongly contemporary finish with incomparable corrosion and abrasion resistance.

Aluminium is exceptionally recyclable, requires minimal maintenance and has proven lifetime performance.

Polyester Powder CoatED ALUMINIUM (PPC)

PPC is an A2 limited combustibility finish.

PPC is a type of dry coating, rather than a conventional liquid paint, and is applied to metal rainscreen as a free flowing, dry powder. The powder is applied to rainscreen panels electrostatically and is then cured under heat to allow it to form a ‘skin’. This electrostatic powder process means we can ensure complete coverage of the panels, even on more complex shapes.

Powder Coating can produce a much thicker coating than conventional liquid coating leaving PPC rainscreen cladding with a hard finish. This is much tougher than normal paint and its strong abrasion and corrosion resistance properties make it extremely durable and long lasting.

If you are looking for a finish to make your project stand out PPC is a great specification choice with a range of 200 standard RAL colours and a wide choice of special effects offer a great alternative to anodised aluminium and stone, natural effects and different textures can be used to add a unique touch to your project.

OPTIMA EDGE Testing

BS 8414-2 refers to the fire performance of external cladding systems and is the test method for non-load bearing external cladding systems fixed to and supported by a structural steel frame.

The BS 8414 test methods were developed by the Building Research Establishment (BRE). They evaluate whether a cladding system subject to fire breaking out of an opening (such as a window) in an external wall, will result in excessive fire spread up the outside of the building and the potential for fire to re-enter at a higher level.

The tests are carried out in specialist laboratories, and are performed on full-scale systems (rather than small-scale samples) incorporating; joints and corner details, fixings, insulation, firebreaks, cavities and other elements of the system construction.

Performance criteria for assessing cladding systems tested using BS 8414 is contained within BR 135 – Fire performance of external thermal insulation for walls of multi-storey buildings. It is important to note that the classification applies solely to the specific external facade system which has been tested.

Any deviations or product substitutions from that which was tested are strictly subject to BS 9414

FIRE TEST – BR135 CLASSIFICATION OPTIMA EDGE – 4MM PPC

Performance criteria of the test was based on BR135 Classification standard.

Optima Edge cladding solid aluminium panels with PPC finish and rockwool insulation

Test was in accordance with: BS8414-2:2020

Any deviations or product substitutions from that which was tested are strictly subject to BS 9414

- Test Report: DLR1854

- Fire Test Performed at: Al Futtaim Element

- Date test performed: October 2020

- Steel framing system (SFS) : 150mm Kingframe SFS

- Insulation : Rockwool 140mm Flexi A1

- Sheathing Board : 12.5mm Siniat Weather Defence Board

- Bracket : HILTI MFT-MFI 155-M-6.5, HILTI MFT-MFI 155-L-6.5

- Horizontal Intumescent Cavity Barrier : Siderise RH25G – 90/30 horizontal intumescent cavity barrier

- Vertical Cavity Barrier : Siderise RVG -90/30 vertical cavity barrier

- Cassette Insert : Siderise open state cassette insert (OSCI)

- Carrier Rails : Sotech Optima Edge Carrier Rails

- Panel : 4mm PC Aluminium Optima Edge Rainscreen

OPTIMA EDGE CWCT TESTING

The CWCT ‘Standard for systemised building envelopes’ gives a framework for specifying building envelopes and provides a ‘Specifiers checklist’ showing information that will change from project to project.

This includes:

- Internal and external environment

- Air permeability

- Thermal performance

- Access and safety

- Design life

Tests performed:

Watertightness – dynamic

Wind resistance – serviceability

Wind resistance – safety

Soft body Impact

Hard body impact

SOTECH Optima EDGE

Certificate Number: 2021/112

Fire Test Performed at: Vinci Technology

Date test performed: December 2020

OPTIMA Edge DOWNLOADS

PLEASE ADD WHAT YOU REQUIRE TO YOUR DOWNLOAD LIST.

Once you have added all the files you require to your download list you can gain access to them using the downloads button in the top right or bottom right of your screen. If you have any issues, comments or questions please get in touch and an expert will be in touch as soon as possible.

SOTECHVR

A NEW WAY TO VIEW OPTIMA SYSTEMS

No VR headset? No problem! SOTECHVR will automatically start a standard 3D version if no headset is detected.

For a fully immersive virtual reality experience, SOTECHVR allows users to examine complete 3D models of our Optima range, change the rainscreen system to a material/finish of your choice, learn more about fire safety and rainscreen testing.